0086-15950972819

Blow molding machine

Injection blow molding machine

Injection molding machine

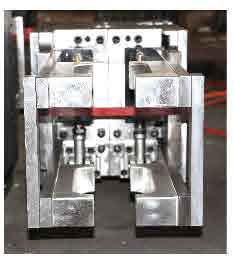

Injection & blow mold

Bitzer Compressor

Water & Air cooler chiller

Bitzer Compressor Set

Gasoline Generator Set

single-cylinder diesel

Lovol,Yanmar & Isuzu diesel

Diesel Generator Set

KN95 type mask machine

flat type mask machine

0086-15950972819

National service hotline

Name | Units | YD80Ⅰ | YD80Ⅱ |

Max, product volume | L | 10 | 10 |

Dry cycle | PC/H | 700 | 700*2 |

Screw diameter | MM | 80 | 80 |

Screw L/D ratio | L/D | 24 | 24 |

Screw drive power | KW | 30 | 37 |

Screw heating capacity | KW | 8-9 | 8-9 |

No, of heating zone | ZONE | 4 | 4 |

Outpul of HDPE | KG/H | 110 | 120 |

oil pump drive power | KW | 11 | 11 |

Camping force | KN | 100 | 100 |

Servo system : optional hydraulic servo system

Electrical control system: it is controlled by imported PLC and Man-machine interface (Chinese or English ) and operated by color touch screen . All process setting ,changing, searching ,monitoring, and trouble diagnosis can be done on the touch screen. Non-contact working principle , the components are endurable.

Hydraulic system: it is controlled by proportional pressure and is provided with Yuken hydraulic components, so it is consistent and reliable

Plasticization system: efficient plasticization twin-screw ensures sufficient and even plasticization

Speed regulating system : frequency variable regulating and alloy steel hard finishing reducer steadily regulate speed with low noise, so they are endurable.

Clamping system and die shifting system: dia shifting and clamping are done by camping mechanism with double straight line trail, so it has high accuracy , low resistance and high speed.

Name | Units | YD80Ⅰ | YD80Ⅱ |

Max,size of mold | MM | 400*500 | 400*500 |

Template size | MM | 400*540 | 400*540 |

Mold stroke | MM | 170-520 | 170-520 |

Max,die diameter | MM | 200 | 200 |

Bolwing pressure | MPA | 0.8 | 0.8 |

Air volume | M³/MIN | 0.8 | 1 |

Cooling water pressure | MPA | 0.3 | 0.3 |

Water consumption | L/MIN | 80 | 90 |

Size of machine | L*W*H | 4.4*2*2.7 | 4.4*2*2.7 |

Weight of machine | TON | 7.5 | 8.5 |